THE

INTEGRATED ENERGY SYSTEM

The Optimum Electrical Power System

for the Cruising Sailboat

©

1989 Tor Pinney - All Rights Reserved

When

a sailor forsakes dockside shore power for the wild blue yonder

of the cruising world, his vessel becomes a self-sufficient

living environment. It has to produce whatever energy is

required to operate the various electrical and electronic

accessories aboard. This entails periodically recharging the

ship's storage batteries. Most sailors accomplish this by

running the engine to drive the stock alternator. Boats with

refrigeration, whether 12-volt or mechanical, run engines as

much as two hours every day to keep the fridge and batteries

topped off. To the long distance or liveaboard sailor, this

translates into considerable fuel consumption and engine wear

over the years. Running a large diesel engine without sufficient

load on it will shorten its useful life, not to mention the

noise it creates.

Ah,

but there are better ways, alternatives to this common,

inefficient method of deriving ship's electrical energy from

running the ship's main propulsion engine. The energy we need is

available from the sun, wind, and water, and from more efficient

fossil-fueled engines. When combined in an integrated energy

system, these contemporary sources can relieve the engine of

double duty as a generator by providing 12-volt power for

operating on board equipment, including refrigeration.

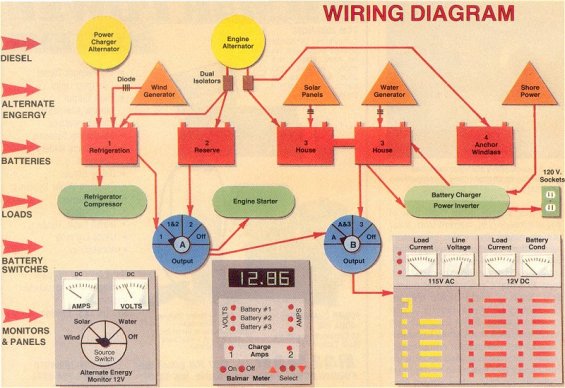

An

"integrated energy system" for the cruising sailboat

is simply a monitored combination of equipment that produces,

stores, and distributes ample 12-volt, DC electricity to meet

the needs of the vessel. The four components of this optimum

yacht electrical power system are the sources, the storage

batteries, the distribution, and the monitors.

12-Volt

Energy Sources

Solar

Panels

The

most fundamental, readily available source of energy on Earth is

the sun. The photovoltaic cell is an effective method for

converting solar light energy into electrical energy. Multiple

photocells (or solar cells) are laminated onto sheets of

paper-thin stainless steel (for marine-grade solar panels) and

sealed with a clear, protective coating of space-age polymers to

form solar panels. Flat, lightweight, and durable, many of

today's solar panels are well suited to use aboard boats.

There's

a place and a need for one or more solar panels on nearly every

cruising sailboat. Their function is to continuously and

silently recharge the ship's batteries during hours of sunlight.

For a vessel with minimal electrical gadgetry, located in a

sunny region, this "trickle charge" may be all that's

needed to keep batteries topped off. It's a valuable, virtually

maintenance-free source of energy in an integrated energy

system.

Solar

panels are available today with either rigid or flexible

housings. Rigid panels are marketed by a host of companies.

They're usually between ½ and 1½ inches thick and come framed

in many rectangular sizes, the handiest being anywhere from one

to three feet wide, and from two to four feet long. On a boat,

they can be screwed flat on any clear deck area or cabin top.

They'll often need a bit of shimming to compensate for camber in

the deck.

However,

solar panels are most efficient when they're angled to face the

sun directly. So it's a good idea to mount them in a manner that

enables you to adjust the direction they face. At anchor, you

could simply lean and lash a panel wherever it will get the most

direct sunlight. But it's probably a better idea to gimbal-mount

panels permanently so that they can pivot and/or tilt to

optimize their angle to the sun. Stern rail mounting

accomplishes this easily. Installing reflectors to direct more

sunlight onto the panel surface can enhance solar panel

performance.

Flexible

solar panels offer even more possibilities for sensible

installations on a sailboat. They come in a variety of sizes

ranging from one to eight square feet. Their chief advantage

over rigid panels is their ability to mount smoothly on curved

or flexible surfaces such as a cabin trunk, a cambered deck, or

a Bimini top. They're lightweight and quite thin - about ¼ inch

- so they're never in the way. Best of all, they can drape over

a curved dodger top or lash, snap or zip onto a sun awning. So

while you're making shade, you're also making electricity. On

the down side, flexible panels may not be as efficient than

their rigid counterparts. Check the rated watts when comparing

solar panels' output.

The

amount of electricity a solar panel produces depends primarily

on the size of the panel and the directness of the sunlight

striking it. Manufacturers tend to advertise absolute maximum

amperage output of their products based on perfect, controlled

conditions where blazing, unobstructed, perpendicular sunrays

strike flat panels. The amperage output is then measured right

at the panel.

In

real life, however, the sky is rarely cloudless, nor the sun at

maximum strength and declination. Rigging and spars will

sometimes cast shadows, decreasing a panel's output. Also, on

board a boat the electricity must travel some distance through

wiring and diodes before it trickles into the battery, further

reducing amperage received. So when a panel is rated for, say, 3

amps (about 36 watts), it will actually yield a net average of

1.5 to 2.5 amps during the brightest part of the day. If a panel

yields 2 amps for 5 hours a day, the batteries have absorbed 10

amp-hours - enough to play the radio and power your cabin lights

that evening.

If

you wire several panels together in series, the power output is

multiplied. A boat in Florida was seen to have eight 33-watt

flexible solar panels mounted on the sun awning. That's 8 panels

X 2 amps (approximate average output) = 16 amps X 5 (bright sun)

hours per day = about 80 amp hours. That's enough amps to power

a hefty 12-volt cold-plate refrigerator/freezer.

Wiring

solar panels is simple. The wires pass inside the boat through a

watertight fitting available at most marine stores. Some solar

panels have a built in diode, a device that allows current to

flow in one direction only. If yours doesn't, then solder a

diode in series in either wire somewhere before the positive and

negative wires connect to the corresponding battery bus

terminals. A Schottky diode is recommended because of its low

voltage drop. This will prevent batteries discharging through

the panels after dark. For safety, you should install both an in

line fuse and an on-off switch between the solar panel and the

distribution panel. You can wire in an ammeter to monitor the

amount of solar energy flowing into your batteries.

Prices

for marine-grade solar panels vary among. Larger panels cost

proportionally more than smaller ones. Expect to pay $300 to

$500 or more for 1 ft. x 4 ft., 40-watt rigid panels, and as

little as around $100 for small sizes that produce one amp or

less.

Wind

Generators

Harnessing

the wind is nothing new to a sailor! With a wind generator, you

can convert wind's kinetic energy into DC current for

around-the-clock battery charging. Of course, this is a more

productive energy source in regions of steady breezes, such as

the trade wind belt.

A

wind generator is a DC generator driven by a propeller. When the

wind spins the prop fast enough, the unit produces a trickle

charge ranging from an amp or two, up to 10 or 15 amps,

depending on wind speed and the propeller and generator size. A

full-size ship's wind generator in the Virgin Islands, where the

trade winds maintain a steady 15-knots much of the time, can

easily produce 6 or 7 amps continuously, well over 100 amp-hours

per day. That's enough to power radios, lights, radar,

television, and a 12-volt refrigerator/freezer!

Beware

of manufacturers' spec sheets that promise amperage output in

very light (5- to 7- knot) breezes. The measurements are taken

at the generator output terminal and only indicate what a

virtually "dead" battery might absorb in these wind

conditions. For DC current to be accepted and stored, the source

voltage must be higher than the voltage in the receiving

battery. A wind generator may well be generating current in

light airs, but at only 9, 10 or 11 volts. So no amps will go

into a battery that's only partially discharged to, say, 12

volts - which is the typical on board scenario - and no charging

will occur. Most of the large-bladed wind generators don't

actually do much charging until the wind exceeds 10 knots. The

small bladed, European style units need a good deal more wind

than that to produce energy.

The

popular American manufactured wind generators feature two- or

three-blade propellers with diameters of four to five feet.

These are hefty generators with relatively good light air

performance. Some European designs are smaller in size, weight,

and blade diameter, with multiple-bladed props. These are less

productive in light breezes, but unlike the large models, they

can be left running in very high wind conditions.

There

are several ways to mount a wind generator on a sailboat. It can

be hoisted into the foretriangle area by a jib halyard while at

anchor, positioned by guys. This allows the unit to pivot and

track wind shifts. But it must be taken down and stowed

somewhere every time you want to get underway, so this

installation is more practical aboard a vessel that tends to

remain anchored for long periods of time. Some skippers mount

their wind generator permanently on the forward side of a

mizzenmast, which eliminates the set-up and tear-down hassle,

but will not allow the wind generator to pivot or face anything

but a head wind. A bow pulpit mount is also rigid, with the

added disadvantages of being vulnerable to damage and dangerous

to crew.

The

most effective solution is mounting on a pole. A pole mounted

wind generator, normally located at the stern, can pivot to face

any wind shift as your boat sails back and forth at anchor or

lies to a current. Best of all, it's always in position to

operate, even under sail! When sailing close hauled, a stern

pole-mounted unit is especially well powered, getting strong

apparent wind funneled into it by the mainsail. The ability to

operate underway makes the pole mount most valuable to cruising

sailors, who need to keep their batteries charged during long

offshore passages. Though this increases the boat's windage

somewhat, it's not enough to matter to a sailboat loaded for

cruising. A further development of the pole mount arrangement is

the bi-pole rig. Looking something like a football goal post on

the stern of the boat, one pole supports the wind generator; the

other, a radar dome or antennae dish. The horizontal crossbar

between the two lends structural support. It's also a handy

place to mount antennae, such as loran and sat nav, where

masthead height isn't imperative. Or you can mount two wind

generators and double the charge. The structure is stiffened by

struts running from each pole to the boat's rail, either fore or

aft, and by one post-to-post diagonal bar that creates the

triangulation necessary for absolute strength on the athwartship

plane.

Pole

mounts are generally custom made and must be very sturdy. The

installation is often strongest if stepped through the deck onto

a block or plate secured to the hull below. With a little

planning, pole mount assemblies can be engineered to disassemble

by unbolting. This will be necessary for boats whose cruising

itinerary includes the canals of Europe, for example, where

masts are unstepped and the vessel's height clearance becomes

critical. Poles (or bi-poles) can be either stainless steel, or

schedule 40 aluminum, the latter being lighter and less

expensive.

A

word of caution: The spinning blade of a wind generator

propeller can be very dangerous when mounted within reach.

Brightly painted or reflective blade tips make the blade more

noticeable to crewmembers.

Many

wind generators come with some kind of over-speed governing

device or brake to protect the unit against damage in very high

winds. Otherwise, they must be manually shut down. In

preparation for extreme wind conditions, they should be taken

down altogether. Generally, they should not be left running when

the boat is unattended for long periods. It may be worthwhile to

wire your wind generator through a regulator to prevent

overcharging of the batteries. Also, they need a diode, either

installed in line or built into the unit itself, to prevent

battery discharge in calm winds.

Wind

generators, especially the larger units, create some noise and

vibration. In moderate conditions, it's a whooshing sound that

passes as unnoticed background noise. In high winds, it's often

a louder fluttering, chopping, whirring noise. Some pole-mounted

wind generators shudder momentarily when they pivot to track an

apparent wind shift, though a new generation of balanced epoxy

props has eliminated this vibration on at least one popular

brand, the Windbugger. Maintenance on wind generators is

minimal. Wooden propeller blades need occasional painting.

Periodically, the brushes and bearings in the generator need

replacing, just as in an automobile alternator. But for the most

part, wind generators just keep on working, night and day, to

keep your ship's batteries charged. After the initial cost of

purchase, usually ranging from $800 to $1100, your ship's

electrical energy is as free as the wind.

Water

Generators

Water

generators can be a valuable addition to the cruising sailor's

integrated energy system. They are the least common alternate

energy source, perhaps because of the inevitable drag created by

towing that extra propeller in the water - 25 to 35 lbs. at 6

knots of boat speed. Or perhaps it's because most boats spend

the majority of their time in anchorages rather than under sail.

A

water generator is a DC generator activated by a propeller towed

in the water. The prop is allowed to freewheel when the boat is

underway. There are four basic ways to set this up, and then

there are variations of these: (1) by trailing a propeller

astern on a cable or braided line. The passing water spins the

prop, which twists the cable and the cable turns the generator

mounted on the stern rail. On some models the prop is attached

to the generator and a cable tows the entire unit; (2) by

mounting a style of water generator that looks like a small

outboard motor. Its lower gear case and propeller are submerged.

(3) By installing a dedicated propeller shaft through the hull

of your boat, letting it freewheel when sailing to turn the

generator. (4) By connecting a generator by way of a belt,

bicycle chain, or gear drive to the ship's main prop shaft and

allowing that to freewheel when sailing.

The

trailing portion of the first, towed type may be damaged or

taken by large fish. The latter two options require custom

design and installation.

Many

wind generators readily convert to water generators, propelled

by the cable and prop method. In fact, wind and water generators

are much the same in terms of cost and maintenance, being the

same machine with different drives. Because the fluid coupling

between water and propeller is much greater than between wind

and propeller, water propulsion yields about double the amps per

knot of speed, generating about 5 amps at 6 knots of boat speed.

To get the same 5 amps from the wind requires about a 12-knot

breeze. For a sailboat making an ocean passage, running down the

trades at 6 knots plus, there's an extra 120 daily amp hours for

the taking! On a cloudy day, on a dead run with little apparent

wind, when the solar and wind energy just isn't coming through,

the water generator will run everything aboard as long as you

keep sailing.

Like

the wind generator, the water generator can be shut off when

your batteries are topped off. Or it can be wired through a

regulator, eliminating this requirement.

Generators

and alternators are very similar machines. Both produce DC

current for charging batteries. Generators are more rugged than

alternators; alternators are the more efficient of the two. If

you'd like to build your own wind or water generator from an

ordinary alternator, the book, The 12-Volt Doctor's Practical

Handbook by Ed Beyn (Spa Creek Instruments, Annapolis, MD),

describes how to do it.

Engine

Alternators

The

alternate energy sources we've discussed so far are all

important ingredients in the integrated energy system. They will

greatly reduce, if not entirely eliminate, the need to run the

engine in order to charge batteries. But the main engine's

alternator can and should be a ready source of electrical

energy, particularly when you're running the engine to propel

the boat anyway.

Most

marine diesel engines come standard with too small an alternator

to cope with the large capacity battery bank of the liveaboard

cruising sailboat. It may well be that with solar, wind, and

water energy sources, you often won't need more than a small

alternator. But in harbor conditions of overcast skies and light

winds, the alternator becomes your only means of recharging the

batteries away from the dock. So a more efficient system is

worth considering.

For

years now we've been hearing about switches that enable us to

manually over-ride the alternator's regulator for quick-charging

the batteries. One of the functions the regulator is to control

the voltage output of the alternator or generator by regulating

the current in the field coil. This eliminates the risk of

overcharging and perhaps destroying the battery. When you

over-ride this function, the alternator can pump full charge

into the batteries without automatically tapering off as the

battery becomes charged.

A

variable rheostat can replace this on-off switch, allowing you

to increase or decrease the field current and, therefore, the

charging rate. But this system requires constant monitoring. You

can damage your alternator by overheating it. The chief danger,

however, is that you only have to forget just once to switch

back to automatic regulation and your batteries will be boiled

and permanently damaged. That's a pretty stiff penalty to pay!

Even with an automatic shut-off wired in, the variable rheostat

is, at best, an old fashioned, partial solution in our quest for

more efficient battery charging. There is an optimum charging

curve which demands precisely decreasing current at specific

battery levels during the charging cycle. Human control, even

devoting full attention during the process, is going to be less

than perfect.

Today's

solution is solid state electronics and high output alternators

with self-governing regulators, such as the series made by

Balmar Products of Seattle, Washington. These units measure the

condition of each battery and automatically regulate charge

according to the ideal charging curve, a more efficient and much

safer alternative to the old manual control methods.

Mounting

a non-standard regulator may require some minor customizing of

the engine brackets. It's possible that the increased side load

on the fan belt may cause bearings to wear rapidly. Before

increasing the size of your alternator, consult the engine

manufacturer for approval.

When

you upgrade your boat's alternator, leave the original unit

mounted in place, if possible, to facilitate a temporary

switchover if the big one ever fails. Otherwise, clean the old

one, spray it thoroughly with light oil, wrap it in plastic, and

store it away in a dry locker. It is always wise for a cruising

sailboat to carry a spare alternator, as well as replacement

brushes and bearings for both units aboard.

The

Power Charger

If

you need more battery charge than you're getting from the sun,

wind, and water generators, there is a diesel powered

alternative to running the engine. Balmar Products markets the

Power Charger, comprised of a four-horsepower Yanmar diesel

engine that drives a large (100-amp or 140-amp) Balmar

alternator. It's compact, weighs just 65 lbs. and burns only a

pint of diesel fuel per hour. For boats with large power

consumption devices like DC refrigeration and microwave oven,

the Power Charger may be a valuable part of an integrated, ample

charging system. From the spare pulley provided, you could drive

a mechanical refrigerator compressor at the same time, or a

scuba compressor, or auxiliary, large capacity water pump for a

deck wash and/or emergency bilge pump. Balmar offers an optional

water desalinator that runs off this unit, producing 20 gallons

of fresh water per hour while you charge your batteries and

fridge!

Installation

isn't too difficult, but the Power Charger really needs a water

cooled (and muffled) exhaust system to be tolerable, not the dry

exhaust offered as standard. Until a water-cooled exhaust system

is made available, installing one yourself is a complex custom

job.

AC

Power Sources

While

a 12-volt DC electrical system satisfies most of the needs of

most cruising boats, there are certainly occasions when 120-volt

AC power is desirable. It's handy for operating hand tools such

as drills and saber saws, galley appliances such as microwave

ovens, blenders, and coffee makers. On large boats the

conveniences of air conditioning, washers, dryers and water

makers may be considered important. Here's an overview of

several different ways to obtain 120-volt AC power aboard your

boat.

Besides

shore power, which of course is restricted to dockside use,

there are four basic ways to have AC power aboard a sailboat:

(1) Carry a portable gasoline or diesel AC generator or install

a heavy duty gen-set; (2) Install an inverter to make AC power

from your ship's DC batteries; (3) Install an engine driven AC

generator; (4) Install an AC electric generator powered by the

ship's DC batteries. A fifth type, seldom if ever seen on boats,

is the emergency standby generator system that operates on LPG

or LNG. Manufactured by Winco in 5,000- and 8,000-watt models,

prices are about $3,400 and $4,100, available from the Hamilton

Ferris Company.

Before

buying, make a detailed list of all electrical appliances aboard

and the number of watts consumed. Include lights stereos, TV's,

hair dryers, tools, air conditioning and so on. Electric motors

(circular saws, air compressors) may require up to five times

their normal operating wattage during start-up; this is called

surge and must be factored into your calculations. List normal

watts and surge watts separately. Though you probably won't run

all appliances at the same time, the power rating of your AC

source (inverter, gen-set, and so on) should exceed by a safe

margin the number of watts you expect to use.

Portable

Generators and Gen Sets

For

many small boat cruisers, fossil-fueled portable generators

provide all the intermittent AC required. Numerous manufacturers

such as Honda, Yamaha, Tanaka and Nissan sell small, lightweight

(20 pounds and up) and inexpensive ($350 and up) generators to

the RV market. Yanmar makes a line of portable diesel

generators, starting at two kilowatts and 127 pounds. While most

are not made of marine-grade materials, common-sense maintenance

and weather protection enable them to survive at sea for many

years. The units stow handily in cockpit lockers. They are

perhaps most useful for powering hand tools and as emergency

back-ups for battery charging.

Larger

boats with electric stoves, air conditioning and other luxury

appliances have little choice but to permanently install a gen-set.

Because electrical equipment in the United States is designed to

operate with a fixed frequency of 60 Hz, the frequency output of

the generator must be fixed at 1200, 1800, or 3600 rpm. The

slower-turning engines are quieter but heavier than the

fast-turning models. The 1800-rpm, four-pole set is a good

compromise for many boats. It makes sense to use the same fuel

(gas or diesel) and exhaust type (air- or water-cooled) as the

main engine.

In

most boats the gen-set may be mounted in the engine room. In any

case, it must be ventilated, sealed from the living cabins,

convenient for fuel and raw-water hook-ups, and mounted on

sturdy structural members. Unless you're very knowledgeable

about such installations, this is a job best left to

professionals. Many of the major manufacturers, including

Norther Lights, Onan, Kohler, Westerbeke and Medalist Universal

Motors, publish useful manuals to help size, select, install and

maintain their products.

Inverters

An

inverter is an electrical device that changes DC from the ship's

batteries to AC and boosts voltage from 12 to 120. Unlike some

older models, the sophisticated modern inverter, such as the

Heart Interface Power Inverter, produces a smooth sine wave

suitable for running TV's and computers. It is a good method of

obtaining intermittent AC power, but of course it is limited by

the capacity of the battery bank - the more ampere-hours in the

bank, the longer the inverter can be run. Unlike the generator,

it is not a power source, but simply a means of changing

electrical current from one form to another. Some principal

manufacturers are Balmar, Dytek, Heart, IMI/Kenyon and Trace;

prices range from about $100 (for a small 100-watt model) to

$2,500 (for a powerful 2,000-watt model with battery charger).

Optional add-ons increase usefulness and cost. A power inverter

is a convenient addition to the integrated energy system on a

cruising boat. And best of all, it doesn't rely on fossil fuels.

Engine-Driven

AC Generators

While

a gen-set is merely an AC generator directly geared to an

internal combustion engine, the engine-driven AC generator just

uses the main engine instead of an auxiliary, dedicated one.

Engine-driven AC generators such as those made by Auto-Gen mount

on or near the main propulsion engine and are driven by belts

and pulleys. Therefore, AC power is available whenever the

engine is run. Auto-Gen's units are available from 2.5 kilowatts

to 6.5 kilowatts and cost from about $2,000 to $2,700.

AC

Electric Generators

Like

an inverter, the AC electric generator "makes" AC from

DC, but not by the same means. The AC electric generator uses

battery power to run a small electric motor, which then turns

the generator. Honeywell is one of several manufacturers; its

units produce from 500 to 1,600 watts. Again, such a device is

limited by the ampere-hour capacity of the battery bank.

There

is no single "right" product for cruising boats. Just

as an integration of two or more 12-volt solar, wind and water

generators helps to meet the varying conditions found under way

and at anchor, a combination of AC power sources offers

versatility. For example, if the gen-set is operated only when

the main engine is shut off, an inverter or engine-driven AC

generator can provide AC under way. It really depends on the

number and type of appliances installed aboard your boat, and

how you use them.

Shore

Power

Many

cruising sailors spend as little time as possible dockside.

Nevertheless, we may at times tie up and plug in the

"umbilical cord," so shore power should figure into

our ship's integrated energy system.

For

our purposes, the 125-volt, AC electricity brought aboard

through the dockside power cable needs to be converted or

rectified into Direct Current at 12 volts. In many countries and

throughout Europe, a boat wired for American voltage will need a

220/110 step-down voltage transformer to avail itself of shore

power. This current can then charge the boat's batteries to

supply all our electrical needs while we're plugged in.

What's

called for here is a marine AC converter/battery charger. This

differs from an ordinary automotive battery charger in two

important ways: (1) The design ensures electrical isolation

between the 125- volt AC circuit and the battery circuit, which

prevents stray currents that pose shock hazards aboard a boat

and could set up corrosive electricity in the surrounding water,

and (2) The converter produces a non-trickle type charge

delivery, which avoids the risk of damaging batteries by

overcharging. The marine charger automatically shuts itself off

when batteries are fully charged, and switches itself back on

when battery voltage drops.

Remember

to shut down any alternate energy sources, like solar and wind,

which aren't self-regulating. Overcharging batteries is one of

the quickest ways to destroy them!

Storage

Batteries

Batteries

are the heart of the integrated energy system. Because the

living environment of a boat requires relatively low amperage

doled out over a long period of time, we use "deep

cycle" batteries - batteries designed for gradual discharge

- to power our lights, radios, and so on. Deep cycle batteries

are built more heavily than standard batteries, which are

designed to deliver lots of amps in brief bursts such as for

starting an engine.

The

first consideration for the battery bank in a successful energy

system is its capacity. To some extent, capacity is determined

by how much space, weight and money we can afford. Most stock

boats do not have enough battery capacity for liveaboard

cruising. As a rule of thumb, the ship's batteries should be

able to supply nominal electrical energy for four 24-hour days

of live-aboard consumption without recharging.

To

compute how much energy you typically consume, see the Sidebar

"Typical Loads For Accessories". For each item,

multiply the amperage it consumes by the number of hours you use

that device per day to give you the ampere-hours (amp-hours)

drawn. For example, you may burn the anchor light for 11 hours

per night. It draws 1.2 amps. So the consumption is 13.2

amp-hours (1.2 amps X 11 hours). You might play the stereo for a

few hours in the evening: 1 amp x 3 hours = 3 amp-hours. Total

up all the amp-hours you've calculated, and you have your

approximate daily electrical energy consumption. Consider that

your usage is quite different during offshore passages, where

running lights, radar, and navigational devices are operating

for long periods. Depending on your cruising style, you might

average this in. Now, multiply the total daily amp-hours times

four. If your batteries can deliver this total without requiring

recharging, you've got an adequate battery bank aboard.

Batteries

cannot deliver their rated capacity. To do so would drain them

"flat", and that's a sure way to shorten the life of a

lead-acid battery. It is healthiest for batteries to be

recharged once they've reached their 50% capacity. The 50%

discharge point of deep cycle, 12-volt batteries is 12.2 volts.

We monitor this from an accurate voltmeter. But even 50% is too

much to expect, because our batteries are not always charged to

capacity. In fact, after normal charging, they're only at about

85%. So, in order to limit discharge to the 50% level, we have

just 35% of the rated capacity of our bank available for use

without recharging (85% charged - 50% discharge level = 35%

available).

This

means we want our 4-day amp-hours to equal 35% of our batteries'

rated capacity. Let's assume a 50 amp-hour daily usage

aboard. That's 200 amp-hours for four days. This indicates a

battery bank rated for about 572 amp-hours (35% of 572 = 200.2),

requiring three or four large, deep cycle batteries. With this

kind of deep cycle battery capacity, there really isn't a need

for a separate, standard engine start battery.

Do

yourself a great favor and invest in top quality batteries.

Their price may be higher at purchase, but their cost will

ultimately be lower when averaged out over years of continued

use beyond the life span of cheaper brands - not to mention the

reliability factor.

Batteries

are best mounted low in the boat because they're so heavy and

can effect boat stability and trim. However, they must also sit

above high bilge-water levels. The less distance between energy

sources, batteries, and loads (distribution panel and

appliances), the better, because power is lost in long wires.

Batteries shouldn't be allowed to get very hot, as they will if

installed in most engine compartments. Heating will shorten

their life considerably. They need to be secured so that they

can't possibly come loose, even if the boat is turned upside

down and shaken. If they're lead-acid batteries, they need to be

in strong battery boxes that will catch any acid that leaks, and

they should be ventilated. Be sure the installation is readily

accessible for routine maintenance.

You

have the option of using pairs of 6-volt batteries, connected in

series, instead of single 12-volt batteries. These may be easier

to move around and install. There's the added advantage that if

one cell goes bad, ruining the battery, you only have to replace

half as much battery.

The

lead-acid battery is the most common 12-volt battery type. But

today there is an alternative: gel packed Dryfit Prevailer

batteries made by Sonnenschein Batteries (Cheshire,

Connecticut). They have several advantages over lead-acid

batteries: They cannot spill acid, they don't form dangerous

gases while charging, they're totally maintenance-free (never

needing water added), and, according to the manufacturer, they

can be discharged flat without harm. The only way to damage

these military-designed batteries is by overcharging them. In

size, weight, price, and longevity they're comparable to top

quality lead-acid batteries.

Typical

Loads for Accessories

Estimated

power consumption of some common on-board devices

DEVICE

AMPS*

Anchor

Light 1.2

Anchor Windlass 75.0

Autopilot 4.0

Bilge Blower 2.5

Bilge Pump 4.0

Cabin Fan 1.2

Cabin Light (incandescent) 1.5

CB Radio (receive) 1.0

Compass Light 0.1

Deck Wash Pump 10.0

Depth Sounder 0.1

Fluorescent Light 0.5

Forced Air Heater 7.0

Foredeck Light 1.7

Fresh Water Pump 8.0

Fuel Pump 3.0

Head Pump 18.0

Horn 3.0

Inverter 1.4

Knot meter 0.1

Loran 1.2

Masthead Tri-color 2.0

Microwave (via inverter) 95.0

Propane Electric Shut-Off 0.7

Radar 3.7

Recording Depth Sounder 0.5

Refrigeration (cycling) 25.0

Running Lights 3.5

Sat Nav (average) 0.3

Spreader Lights 6.0

Spotlight 10.0

Steaming Light 1.0

SSB Radio (receive) 2.0

SSB Radio (transmit) 25.0

Strobe Light 0.7

Tape Player 1.0

VHF Radio (receive) 0.3

VHF Radio (transmit) 4.5

Water Maker (small 12-volt) 3.6

Weather Fax 2.4

Wind Speed indicator 0.1

To

estimate the amperage draw of other 12-volt devices, divide

their rated watts by 12.

Distribution

If

the batteries are the heart of the integrated energy system,

then the distribution system is the brain. Distribution of

electricity aboard happens in two stages: First, source energy

is consigned to one or more of the batteries. Then the stored

energy in the batteries is directed to each device as needed.

Source

energy other than that of the alternator (i.e., current from

solar panels, wind and water generators, battery chargers) may

be channeled through switches enabling us manually to determine

the target battery, the battery to receive that charge. But

that's not necessary. Each of these trickle charges can simply

be wired directly to one specific battery. If, for example, we

have dedicated one battery to power a 12-volt refrigerator

compressor, usually the heaviest load aboard, we can expect this

battery to be depleted daily. It's going to need almost constant

replenishment of energy. If the wind generator is the most

consistent producer aboard, we can wire it to this refrigerator

battery (we'll call it battery #1). In breezy conditions, the

Windbugger will generate 100 amp-hours or more daily, enough to

keep Battery #1 topped off.

Now,

suppose the wind is up and the wind generator is cranking out a

steady 9 amps - over 200 amp hours in 24 hours. That's more than

the fridge battery can use. We'll want to share some of those

spare amps with other batteries. We could use some to top off

the reserve or starter battery (#2) if we've dedicated one, or

to supplement the "house" bank (#3). This is done

through a pair of master battery selector switches, through

which we can connect the #1 with #2, or #1 with #3, or #2 with

#3 (see Wiring Diagram). Electricity will flow from whichever

bank has the higher voltage to the bank that has the lower

voltage. Like water, voltage seeks its own level. Therefore,

soon after two batteries are connected through the switch,

they'll level off at the mean voltage. In our example we'll

connect the wind-charged fridge battery (#1) to the house bank

(#3). First they'll level off. Then, as the wind generator's

trickle charge enters Battery #1, half of it will bleed over to

#3, keeping them both charged to the same level.

Conversely,

when the refrigerator compressor cycles on while #1 and #3 are

connected, then it will be drawing from both batteries

simultaneously. There are times when this may be desirable. The

main thing is that we are in control.

The

one energy source that ought to be "automatic" is the

alternator. This can and should be self-distributing as well as

self-regulating. By wiring the alternator through isolators, its

charge is directed to all batteries. A dual isolator enables you

to charge 2 separate battery banks simultaneously. A pair of

dual isolators charges 4 banks, regardless of the battery

selector switch positions. The isolators determine which

batteries need how much of the charge, and distribute the

alternator's amperage output accordingly. So if the house bank

is low when you fire up the engine, but the refrigerator battery

is well charged from alternate sources, then the alternator will

jam maximum amps into the hungry #3 battery, while sending only

a trickle to #1. Finally, as all batteries approach a charged

condition, the self-regulating alternator gradually reduces its

output to zero.

Once

energy is directed to and stored in the batteries, it can then

travel to the ship's electrical panel, stage two of the

distribution system. The modern panel includes rows of breaker

switches, each one labeled for its load device. A word of

warning: Many panels have AC and DC on the same board, albeit in

separate rows. If you're ever poking around behind such a panel

while plugged into shore power, and accidentally cross an AC

terminal with a DC terminal with your screwdriver, a massive

dose of electricity may be instantly distributed into you, or,

through the negative grounded engine, into the surrounding

water. Someone could get electrocuted! All 120-volt AC breaker

panels should be physically separated from 12-volt DC panels.

They rarely are, so be careful!

Many

boat manufacturers locate the electrical panel in the nav

station. Frankly, there are more useful things - navigational

electronics, radios, etc. - that deserve this prime space.

Panels can be placed in almost any convenient spot away from

possible spray from hatches; the nearer to the batteries, the

better.

From

the panel, myriad wires run throughout the boat to the

appliances. They should be color coded and recorded in diagram

form for future reference. Neat, tie-wrapped bundles of wire,

well secured to bulkheads along their route, are the mark of a

professional installation. Most devices call for an in-line fuse

of proper amperage, a smart precaution even if the panel's

breakers perform the same protective function. In general,

unless you're especially well versed in wiring, you should hire,

or at least consult, a professional marine electrician regarding

wire sizes, insulation, connections, diodes, fuses, switches,

and safety precautions. Faulty or improper wiring is a prime

cause of fires on boats.

|

|

From

Top Left

A

Power Charger will guarantee ample, efficient

recharging for the #1 (refrigerator) battery and,

through the switches, the #2 and #3 banks as well.

The wind generator also feeds directly to Battery

#1.

The

main engine's large alternator charges all battery

banks, each according to need, distributed by a pair

of dual isolators.

Battery

#2 is a reserve battery. It sometimes functions as

an engine starter battery, and sometimes as a second

refrigerator battery, as determined by the switches'

positions.

Solar

and water generators feed the #3 (house) battery

bank. This house bank, which is shown as a pair of

12-volt batteries in parallel, also receives the

battery charger's input when shore power is

available. When shore power is disconnected, the

power inverter can supply 120-volt AC to the ship's

electrical sockets, drawing 12-0volt current from

the #3 bank.

The

#4 battery is dedicated to an electric anchor

windlass. It is mounted far from the rest of the

system, requiring long wire runs. For this reason,

and since it normally is used with the engine

running, Battery #4 is only charged by the engine

alternator and cannot interact with the other banks

through the switches, as can Batteries #1, #2 and

#3.

The

Switches

The

system requires two four-position battery switches.

Switch A receives Batteries #1 and #2. The output of

this switch is used for engine starting. If Switch A

is pointing to #1, then that battery will be called

upon to start the engine (#1 is already feeding the

refrigerator directly). The 1&2 setting combines

these two batteries in parallel, for boosting the

refrigerator battery's capacity, or for engine

starting with two batteries. Set to #2 alone, it

uses the reserve battery for starting.

The

output of Switch A also goes to the A-terminal on

Switch B. Switch B is also wired to the #3 battery

bank. In the middle (A&3) position, Switch B

connects the #3 bank with whatever Switch A is set

to. So, if Switch A is set on #1, and Switch B is

set on A&3, then battery banks #1 and #3 are

connected. This would be a useful setting when shore

power is connected, enabling the battery charger's

charge to flow into #3, then onward into #1 to keep

the refrigerator battery topped off as well as the

house bank. Output of Switch B goes to the

distribution panel.

Monitors

The

alternate energy monitor illustrated uses a pair of

meters - a DC amp meter and a DC voltmeter - to

monitor three alternate energy sources. The meters

display the output of whichever source the

four-position switch is set to: wind generator,

solar panels, or water generator.

The

Balmar digital meter displays the precise voltage of

any one of three battery banks. It also displays the

number of amperes flowing into or out of each

battery, and how many amps are being produced by

either of two sources (one source normally being the

engine's alternator).

The

distribution panel shown also houses four meters:

120-volt

AC Load Current - how many amps of AC we are

consuming

120-volt AC Line Voltage - how much AC voltage is

being supplied

12-volt DC Load Current - the total DC amps we are

using

12-volt DC Battery Condition - approximate battery

voltage level

|

Monitors

and Controls

The

monitors are the eyes of the integrated energy system. By

observing how much current passes in and out of the system, and

how much we have stored, we can more effectively control and

conserve electricity aboard. We can also protect the system from

damage due to negligence.

Monitors,

for our purposes, are meters. There are two basic types we can

use: analog (needle-in-a-window) meters; and the newer,

extremely accurate, solid state digital meters with LCD

readouts. The latter are the better choice where accuracy is

desired, such as observing battery voltage.

Monitoring

the incoming source energy can be accomplished with simple

needle meters. One AC voltmeter can display shore power when

we're plugged in dockside and an AC ammeter will indicate how

much load we're putting on the AC system. This will help us

avoid overloading the 30-amp circuit that moderate-size

sailboats commonly use. Away from the dock, the same AC meters

will indicate voltage provided by, and amps drawn from the power

inverter, if we've installed one.

We

want to know how much energy our alternate sources are

providing. DC volt meters, wired to the solar, wind, and water

generators, illustrate at what point these units are developing

enough voltage to start pumping amps into the batteries. Even

more useful are DC ammeters. Wired to the source generators,

they register how many amps each unit is producing. Knowing

this, we can easily judge whether these sources are keeping pace

with our consumption, and which ones are helping the most at

what times. A single voltmeter and a single amp meter can

monitor all three alternate energy sources one at a time if you

wire in a three-way switch to each meter.

Similarly,

one analog voltmeter can monitor all the batteries if a switch

is wired in line to connect the meter with each battery

separately, one at a time. An off position in the switch will

conserve power, avoiding the inevitable small draw of a meter in

constant operation. One DC ammeter should monitor the total

amperage consumption aboard.

It's

imperative that we watch the batteries closely. Neglecting them

will surely result in damage. We need to know when our batteries

reach the 50% discharge point (12.2 volts) to avoid deep-cycle

discharge, which shortens battery life. Conversely, we must

guard against overcharging that can ruin a battery.

The

old fashioned way to determine lead-acid battery condition is by

measuring the specific gravity of the sulfuric acid and water

electrolyte with a hydrometer, a glass tube with a calibrated

float inside and a rubber suction bulb on top. This is still a

good gauge for identifying a bad cell. But the measurement is

affected by temperature variations, making it a less than

perfect means of determining voltage. An accurate voltmeter is

needed for this. In the analog meter category, an

"expanded-scale suppressed-zero" meter is the best

choice. It ignores voltages below 10 or 11, because a battery is

completely dead and depleted of useful charge at that point

anyway. Instead, this meter's scale makes it easier to read

exact fractions of volts by only displaying levels between, say,

11 and 16.

The

most accurate meters are the digital models. Balmar makes one of

the best. It will display the voltage level of three separate

batteries (measured to the 100th of a volt!), and the amperage

passing in and out of each. It also monitors the amperage output

of two energy sources, one normally being the alternator. The

selector button lets us choose what information is displayed on

the LCD screen. With this monitor system, it's easy to check the

voltage of each battery with a glance, several times daily. We

can also see instantly whether a battery is gaining or losing

amps, as loads that are consuming power compete with sources

putting energy back in.

As

you get used to making quick, regular surveys of your ship's

energy components, you will find your confidence increasing with

your ability to monitor and control your integrated energy

system.

Summary

Today,

more and more sailors are extending their cruising range and,

correspondingly, the length of time that their boats must

provide a complete living environment. Electrical energy systems

aboard small and mid-size sailboats have come a long way to keep

pace with the growing demand for civilized amenities afloat. We

can have for our convenience, our comfort, and our safety ample

12-volt and 120-volt power for all normal marine and household

uses. An integrated energy system will provide it continuously

and efficiently. More power to you!

~

End ~

Back

to List of Tor's Tips